The Importance of Crankshaft Engine in Diesel Mechanisms

The crankshaft engine stands as a critical component within the realm of diesel mechanics, influencing not only performance but also reliability and efficiency. Understanding its functionality, maintenance, and the market for parts can significantly benefit businesses involved in diesel engine parts and spare parts supply. In this article, we will delve deep into the workings of crankshaft engines, the significance of high-quality parts, and why choosing the right suppliers like client-diesel.com is vital for success in this field.

What is a Crankshaft Engine?

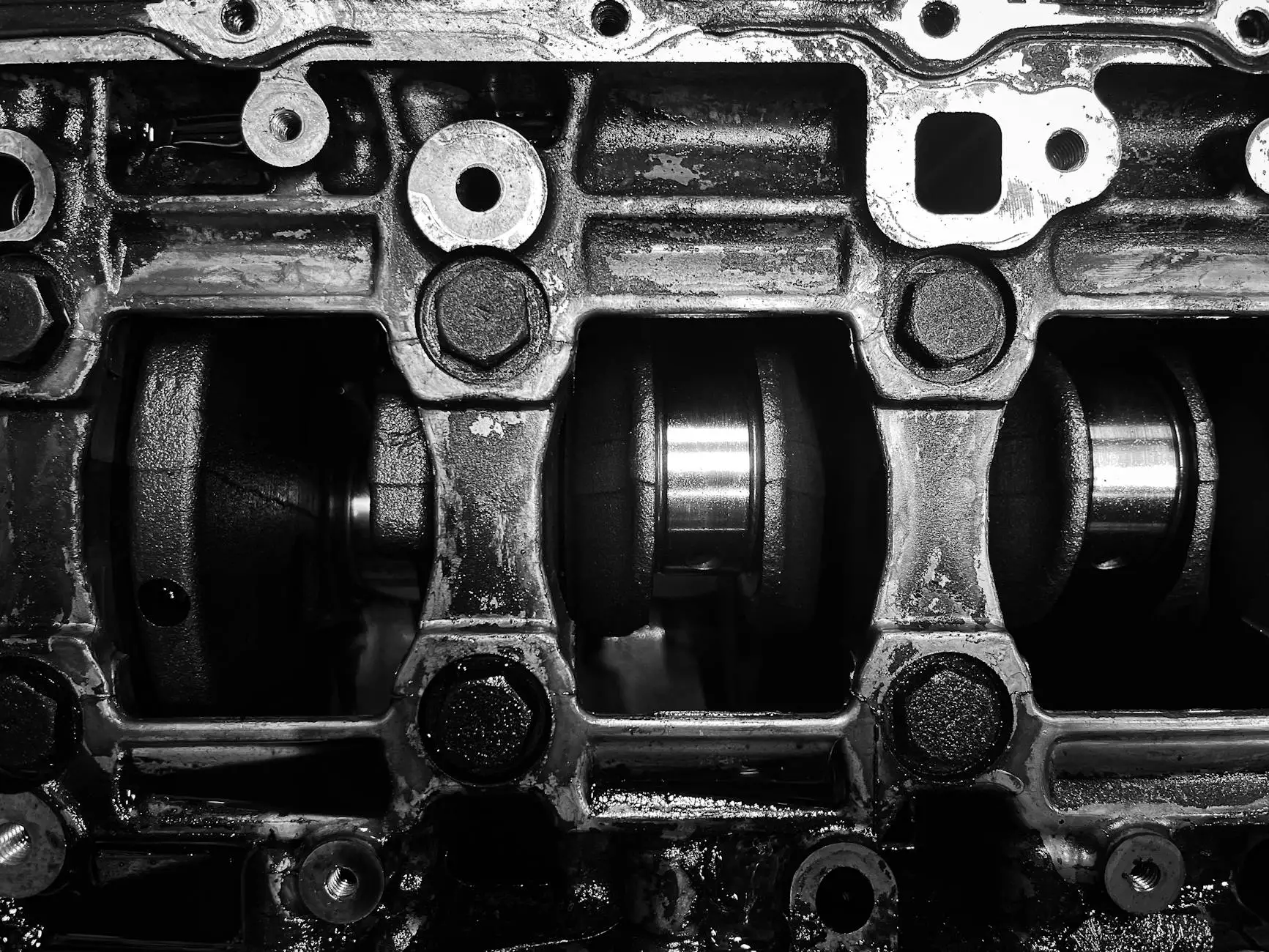

A crankshaft engine refers to the type of internal combustion engine where the crankshaft plays a vital role in converting the linear motion of the pistons into rotational motion. This conversion is key to powering the vehicle's wheels or performing work in various industrial applications. The crankshaft is often hailed as the heart of the engine, and its integrity is paramount for efficient operation.

Components of a Crankshaft Engine

The functionality of a crankshaft engine hinges on several essential components, each serving a distinct purpose:

- Crankshaft: The main rotating shaft responsible for converting motion.

- Pistons: Move within the cylinders, pushing against the crankshaft.

- Cylinders: Houses the pistons and is where the combustion process takes place.

- Connecting Rods: Connect the pistons to the crankshaft, transferring the force generated by combustion.

- Flywheel: Helps to balance the engine and maintain smooth operation.

How a Crankshaft Engine Works

The operation of a crankshaft engine can be broken down into a series of steps:

- Intake Stroke: The intake valve opens, allowing air and fuel to enter the cylinder.

- Compression Stroke: The piston moves up, compressing the air-fuel mixture.

- Power Stroke: The spark ignites the mixture, pushing the piston down, which moves the crankshaft.

- Exhaust Stroke: The exhaust valve opens, allowing combustion gases to exit the cylinder.

As this cycle repeats, the crankshaft converts the vertical motion of the pistons into rotational kinetic energy, enabling vehicles to move forward and perform their necessary functions.

The Significance of Quality Parts

The importance of using high-quality parts in a crankshaft engine cannot be overstated. Inferior parts can lead to numerous issues, including:

- Increased Wear and Tear: Cheap, low-quality materials can wear down faster, leading to frequent replacements.

- Engine Imbalance: Poorly manufactured crankshafts can create vibrations that affect the entire engine's operation.

- Poor Performance: Low-quality parts can diminish the overall power output and fuel efficiency.

Investing in quality parts ensures not only the longevity of the crankshaft but the entire engine as well, ultimately translating to better performance and lower operational costs.

Finding the Right Spare Parts Suppliers

For businesses reliant on diesel engine components, selecting a reputable supplier is vital. Here are some tips to consider when searching for spare parts suppliers for crankshaft engines:

- Reputation: Research suppliers' backgrounds and check customer reviews.

- Product Range: Ensure they offer a wide variety of crankshaft engine parts.

- Quality Assurance: Work with suppliers that guarantee the quality of their products.

- Customer Service: Opt for suppliers known for their responsive and helpful customer support.

- Competitive Pricing: Compare prices, but remember that the lowest price may not always indicate the best value.

Top Crankshaft Engine Parts to Consider

When sourcing parts for crankshaft engines, it is beneficial to focus on certain essential components. These include:

- Crankshaft Assemblies: Complete assemblies designed for specific engine models.

- Crankshaft Bearings: Critical for supporting the crankshaft's rotation.

- Connecting Rods: Essential for the transfer of force from the pistons.

- Oil Seal Kits: Important for preventing oil leaks.

Understanding Diesel Engine Maintenance

Proper maintenance of a crankshaft engine is crucial for maximizing performance. Here are some key practices:

- Regular Oil Changes: Engine oil lubricates the crankshaft and prevents overheating; regular changes are necessary.

- Inspection of Components: Regular checks for wear and tear can help identify problems before they escalate.

- Professional Servicing: Schedule routine maintenance with professionals experienced in diesel engine systems.

- Use Quality Fuels: Ensure you're using high-quality diesel fuel that enhances engine performance.

Future Trends in the Diesel Engine Market

The future of the diesel engine market is poised for significant changes. Innovations in technology and growing environmental regulations are leading to enhancements in engine design and the pursuit of cleaner fuels. Key trends include:

- Increased Efficiency: Advances in engineering are aimed at producing more power while reducing fuel consumption.

- Low Emission Technologies: Development of advanced post-combustion systems will reduce harmful emissions.

- Hybrid Systems: The integration of electric systems in diesel engines to improve efficiency and reduce reliance on fossil fuels.

- Smart Engine Controls: Adoption of AI-driven controls to optimize performance in real-time.

Conclusion

In conclusion, understanding the crankshaft engine and its components is essential for anyone involved in the diesel engine sector. With an emphasis on quality parts, proper maintenance, and selecting reputable suppliers such as client-diesel.com, businesses can enhance their operations and achieve better performance outcomes. The future looks promising, marked by technological advancements and a shift towards sustainability. As we advance, embracing these changes will be key to thriving in the diesel engine market.