Unparalleled Excellence in Plastic Injection Mold Manufacturing: DeepMould’s Leadership in Metal Fabrication

Introduction: The Critical Role of a Plastic Injection Mold Manufacturer in Modern Manufacturing

In the rapidly evolving world of manufacturing, precision, efficiency, and innovation are the cornerstones of success. At the heart of many manufacturing processes lies the plastic injection molding industry, which relies heavily on high-quality plastic injection molds to produce intricate and durable plastic parts. As a result, the role of a plastic injection mold manufacturer is more vital than ever, especially within the wider context of metal fabricators. Today, companies like DeepMould stand out for their dedication to delivering advanced tooling solutions, ensuring customers meet both quality standards and production demands.

Understanding the Significance of a Plastic Injection Mold Manufacturer in the Supply Chain

From automotive components and consumer electronics to medical devices and packaging, the demand for customized plastic parts is unparalleled. A plastic injection mold manufacturer plays a pivotal role in creating the tools and molds needed for mass production. Their expertise directly influences:

- Product quality — Precise molds ensure parts are consistent, functional, and aesthetically appealing.

- Production efficiency — High-quality molds reduce cycle times, minimize defects, and increase output.

- Cost-effectiveness — Durable molds cut down long-term maintenance and tooling costs.

- Innovation capacity — Advanced tooling enables complex geometries and intricate designs that meet today's market demands.

Within this vast landscape, companies such as DeepMould excel by integrating cutting-edge metal fabrication techniques with pioneering mold design strategies, making them a trusted partner for OEMs and leading brands worldwide.

Why DeepMould is Recognized as a Premier Plastic Injection Mold Manufacturer

Comprehensive Capabilities in Metal Fabrication and Mold Design

DeepMould specializes in metal fabrication, a fundamental pillar that underpins their plastic injection mold manufacturing process. Their mastery in handling various metals, such as steel, aluminum, and alloys, ensures the creation of strong, durable, and precise molds tailored for specific plastic materials and production requirements.

State-of-the-Art Technology and Equipment

Investing in advanced machinery such as CNC machining centers, EDM (Electrical Discharge Machining), wire cutting, and laser engraving allows DeepMould to produce complex mold components with unmatched precision. This technological edge guarantees the production of high-tolerance molds that meet stringent international standards.

Dedicated R&D and Customization

DeepMould's Research and Development team continuously innovates, offering customized solutions aligned with client specifications. They collaborate closely with customers, translating ideas into high-functioning molds that boost productivity and minimize scrap rates.

End-to-End Service and Support

The company offers a full spectrum of services, including design consultation, prototype development, mold manufacturing, and post-production support. This comprehensive approach ensures smooth project flows, faster turnaround times, and cost-efficient production.

Quality Assurance and Certifications in Mold Manufacturing

As a top-tier plastic injection mold manufacturer, DeepMould adheres to rigorous quality standards. Their manufacturing processes are certified under ISO 9001 and other relevant standards, ensuring consistency, reliability, and compliance across all projects. Stringent testing phases include:

- Dimensional accuracy checks

- Material integrity testing

- Cycle testing

- Durability assessments

This commitment to quality delivers long-lasting molds that withstand high-volume production environments, ultimately translating into cost savings and enhanced customer satisfaction.

Innovative Technologies and Techniques Employed by DeepMould

3D Modeling and Simulation

DeepMould utilizes advanced CAD/CAM software and simulation tools to optimize mold designs. These technologies allow for virtual testing of the mold's performance before manufacturing, reducing errors and saving time and money.

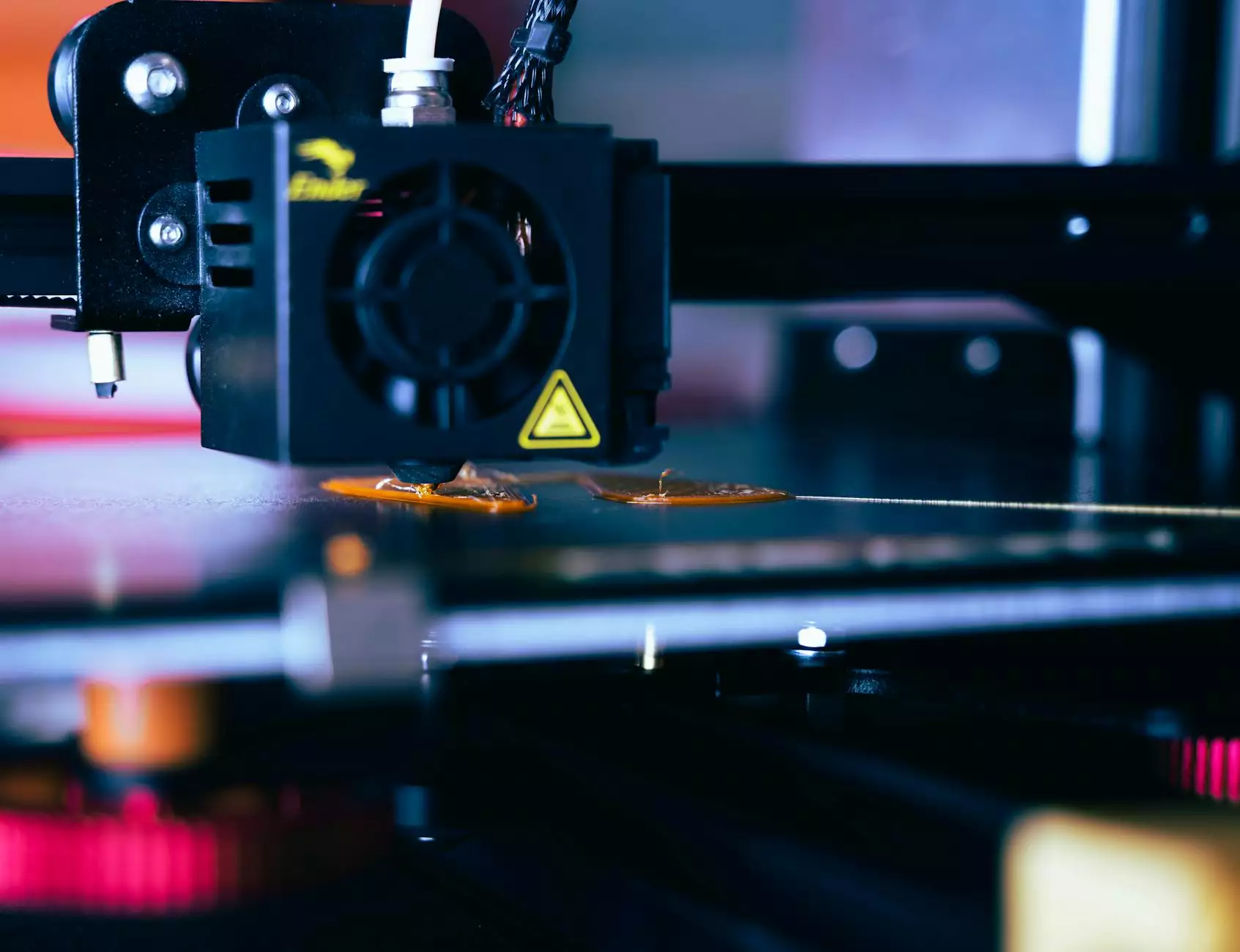

Rapid Prototyping and Additive Manufacturing

Fast prototyping options enable clients to visualize and test molds early in the development cycle. DeepMould leverages 3D printing to create trial models, facilitating design validation and modification with minimal delays.

Smart Manufacturing and Automation

Automation solutions, including robot-assisted machining and automated inspection, ensure consistent quality and reduced human error. Embracing Industry 4.0 principles, DeepMould streamlines production workflows to meet demanding deadlines and maintain high standards.

The Process of Manufacturing High-Quality Plastic Injection Molds

Step 1: Concept & Design

Initial consultation involves understanding client needs, selecting appropriate materials, and designing the mold with precision CAD software. DeepMould’s engineers collaborate closely to ensure the design meets all functional and aesthetic requirements.

Step 2: Prototype & Validation

Prototype molds are produced to test form, fit, and function. Using rapid prototyping technologies, modifications are incorporated immediately based on testing feedback.

Step 3: Precision Manufacturing

The final mold components are manufactured using high-precision machining techniques. DeepMould's metal fabrication team ensures that each part meets tolerances, surface finish, and durability specifications.

Step 4: Assembly & Testing

The assembled mold undergoes rigorous testing, including trial runs to validate performance against specifications. Fine-tuning is performed to optimize molding parameters and ensure flawless cycle times.

Step 5: Delivery & After-Sales Support

Post-production, DeepMould provides comprehensive support including installation, maintenance, and periodic repairs, prolonging the mold's lifespan and ensuring sustained efficiency.

Advantages of Partnering with DeepMould as Your Plastic Injection Mold Manufacturer

- Unmatched expertise in metal fabrication that guarantees robust molds

- Custom solutions tailored uniquely to your project

- Fast turnaround times without compromising quality

- Competitive pricing due to efficient manufacturing processes

- Comprehensive service from design to post-sales maintenance

- Global reach with satisfied clients across industries and regions

Driving Business Success Through High-Quality Mold Manufacturing

Investing in superior plastic injection molds from a reputable plastic injection mold manufacturer like DeepMould does more than just ensure product quality—it fundamentally improves business operational efficiency, accelerates time-to-market, and enhances brand reputation. Companies leveraging high-precision molds can adapt swiftly to market trends, innovate with complex product designs, and meet demanding customer expectations effectively.

Why the Metal Fabricators Industry and DeepMould Go Hand-in-Hand

The metal fabricators industry is integral to creating molds because it provides the high-tolerance, durable components necessary for precise plastic injection molding. DeepMould’s expertise bridges the gap between metal manufacturing and plastics processing, delivering solutions that combine strength, accuracy, and longevity. This synergy ensures that molds are not only capable of sustaining extensive production runs but also adaptable for innovation and design evolution.

Conclusion: Your Partner for Excellence in Mold Manufacturing

Choosing the right plastic injection mold manufacturer is crucial for the success of your product development and production processes. DeepMould has established itself as a leader in the industry through relentless commitment to quality, innovation, and customer-centric solutions. From initial design to final testing, the company’s mastery of metal fabrication and advanced manufacturing techniques ensures that every mold produced supports your business goals.

In today’s competitive market, partnering with a reliable, experienced, and innovative metal fabricator who specializes in plastic injection molds can be your key to achieving superior product quality, cost efficiencies, and market agility. DeepMould’s comprehensive approach makes them the ideal choice for businesses seeking long-lasting, high-precision molds that lead to long-term success in manufacturing.

To learn more about how DeepMould can elevate your manufacturing capabilities, visit DeepMould.net today and experience excellence in metal fabrication and plastic injection mold manufacturing.